- Thermocouples

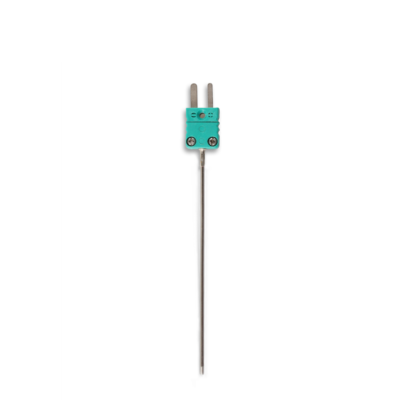

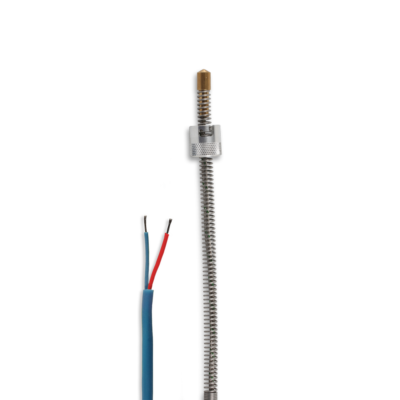

- Screw-in thermocouple

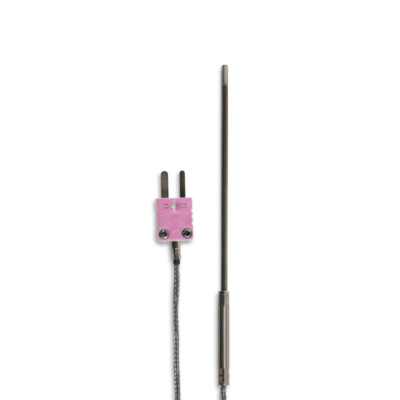

- Plug-in thermocouple

- Dipstick-Thermocouples

- Wire thermocouple

- Sheathing-tube thermocouples

- Sheathed thermocouple

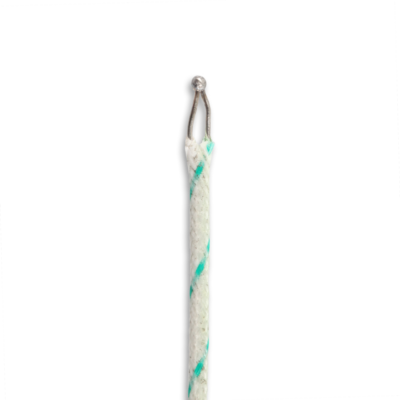

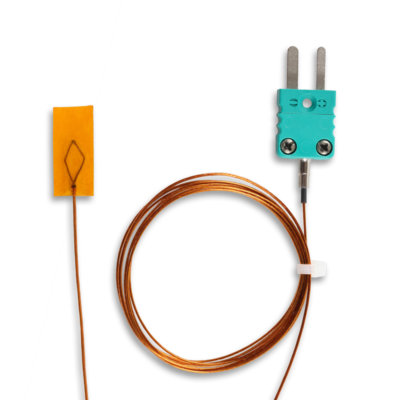

- Surface thermocouple

- Screw-in resistance thermometer

- Plug-in resistance thermometer

- Wire resistance thermometer

- Sheating tube resistance thermometer

- Sheathing resistance thermometer

- Accessories Thermocouples

- Surface resistance thermometer

- Sheathed thermocouple with terminal head

- Thermo connectors

- More products

Thermocouples

Thermocouples are essentially distinguished by their design and the conductor material used.

1. Designs

2. Principles

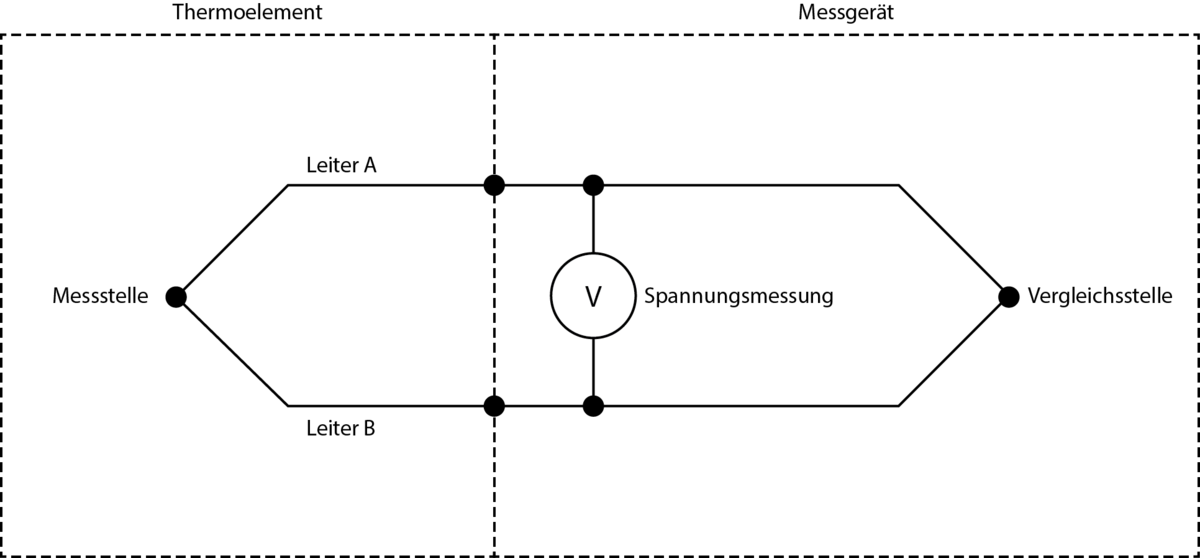

We have been working with every possible combination of thermocouple for over 25 years, and to provide you with a better understanding of this subject, we’d like to explain the functional principle behind them. A thermocouple is made up of two metallic conductors. The conductors are made up of different materials that are connected at both ends (Figure 1). At one end is a measuring point and at the other the reference junction.

Figure 1: Thermocouple connection diagram

If there is a difference in temperature between the measuring point and the reference junction, the material pairing causes a temperature-dependent voltage between conductor A and conductor B known as thermoelectric voltage. This thermoelectric effect was discovered in 1821 by Thomas Johann Seebeck and now bears his name (Seebeck effect). The thermocouple’s measuring point must accept the temperature of the medium being measured in order to measure its temperature. If it does, the voltage measured can be used to determine the temperature. For correct measurement, the temperature of the reference junction must remain constant in order to measure any change in thermoelectric voltage following a change in temperature at the measuring point. To ensure correct measurement, modern-day measuring devices use three different methods.

- The first method uses a reference junction thermostat which maintains the reference junction at a constant temperature of 50 °C, for example. A second thermocouple with the same metal pairing is installed as the reference junction.

- The compensation method is based on temperature-dependent bridging, which permanently establishes a reference junction voltage equal to that of a thermocouple at 20 °C.

- There is also the option of digital correction. In this case, the temperature of the reference junction is measured with a temperature-dependent resistor and the device numerically corrects the temperature measured at the thermocouple.

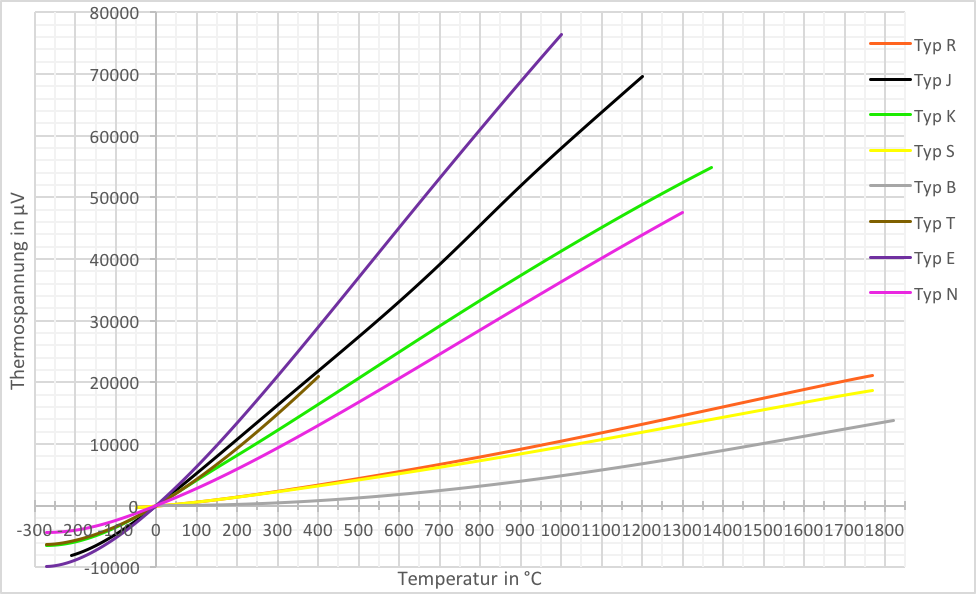

The choice of thermocouple, adapted to the measuring conditions, is crucial for successful and accurate temperature measurement. Thermocouples are available with various material pairings, and for simplification each material pairing has been assigned a typification letter. To find the thermocouple appropriate for the application, a type is first determined using the temperature range to be measured.

Industrial thermocouples can play an essential role in production processes and quality assurance in all branches of industry. Heat treatment or combustion processes are very vulnerable to toxic and corrosive environments, so industrial thermocouples help protect them through a variety of thermowell materials. Industrial thermocouples are designed to be robust, reliable and accurate in their measurements, giving industrial workers peace of mind about their processes. We at Therma GmbH have specialized in precisely these areas of application for industrial thermocouples.

2.1 Thermocouple temperature ranges according to DIN EN 60 584

| Standard | Type | Material | Maximum Temperature Class 1 | Defined up to |

|---|---|---|---|---|

| DIN EN 60 584 | J | Fe-CuNi | +750 °C | +1,200 °C |

| T | Cu-CuNi | +350 °C | +400 °C | |

| K | NiCr-Ni | +1,000 °C | +1,372 °C | |

| E | NiCr-CuNi | +900 °C | +1,000 °C | |

| N | NiCrSi-NiSi | +1,000 °C | +1,300 °C | |

| S | Pt10Rh-Pt | +1,600 °C | +1,768 °C | |

| R | Pt13Rh-Pt | +1,600 °C | +1,768 °C | |

| B | Pt13Rh-Pt6 | +1,700 °C (Class 2) | +1,820 °C |

The most commonly used type of thermocouple is type K since it covers a wide range of temperatures and the limit deviation is low. The procurement costs of the type K element are comparatively low. Thermocouple types R and S, due to the more expensive precious metals and lower thermoelectric voltage used in them, are only used for temperatures over +1,000 °C. Type B elements are used only from +1,300 °C, and in a protective tube they can even be used at temperatures up to +1,800 °C.

Figure 2: Thermoelectric voltage

Visit our online shop, where we offer a wide selection of thermocouples. If you should have any further questions, please contact us. Our many years of experience means that we are experts at designing thermocouples. We are therefore more than happy to help you when it comes to choosing the right thermocouple for your application. If you have any special requests, we can even develop customised products that are adapted to your measuring conditions for you.

Typical area of application |

Pros |

Cons |

|---|---|---|

|

|

|

Images of thermocouples

Powerful thermocouples for all measuring conditions

Temperature measurement is a science that has been researched for hundreds of years and plays an important role in many industrial sectors. While a simple thermometer from the hardware store is sufficient to measure the outside or room temperature under normal conditions, the extreme temperature conditions in laboratories and in development require special types of thermocouples that deliver reliable results even at temperatures above 1000 degrees Celsius. With over 25 years of experience in thermocouples, we can not only offer you the common models such as the thermocouple type K or thermocouple type S, but also advise you on individual solutions. You can buy a thermocouple from us and our experts in industrial temperature measurement technology will find the right accessories for you, such as plug connections, compression fittings or transmitters. In addition, we also offer modern display devices and accessories for motorsport in our shop for thermocouples.

Thermocouples and how they work

Basically, temperature measurement in industry and laboratories works according to the Seebeck effect. This physical effect, named after its discoverer Thomas Johann Seebeck, which has been known since 1821, makes use of the temperature-dependent voltage of metallic conductors. This is also known as thermal voltage and, in addition to the metallic conductors, also requires a measuring point and a reference point. Today, thermoelectric voltage is used in almost all temperature conditions by adjusting the metallic conductors of the thermocouples. For example, iron, nickel or chrome perform differently when exposed to high temperatures. The different types of thermocouples are used accordingly in order to achieve constant and reliable measurement results. The material pairings thus cover ranges from around 350 degrees Celsius to 1800 degrees Celsius.

The diverse areas of application of thermocouples

All of our thermocouples are standardized according to DIN EN 60 584 and are subjected to the most precise quality controls. The K thermocouple is used particularly frequently in industry, laboratories and development. This is due to the fact that the type K thermo-cable covers a relatively wide temperature range and also only allows a small limit deviation. In comparison, the NiCr Ni thermocouple has lower acquisition costs. In contrast, the type R and S thermocouples are more expensive because the precious metals used are more sought-after raw materials. While the thermocouple type J and thermocouple type T move with temperature ranges well below 1000 degrees Celsius at the lower end of the scale, the temperature sensor with type B can withstand over 1800 degrees Celsius and measure correctly when using a protective tube.

The usual measuring methods of thermocouples

Three different methods of temperature determination are used today for reliable and accurate measurement results. First, a reference junction thermostat is used, which ensures that the reference junction maintains a constant temperature. The same pairing of metallic conductors, for example nickel chromium and nickel, is used for the temperature sensor type K for the reference junction. In addition, a compensation method is used for thermocouples, which is based on a bridge circuit, which is also temperature-dependent and produces a reference junction voltage that is comparable to a thermocouple at 20 degrees Celsius. The third method used in parallel for temperature measurement with the smallest possible deviation is the digital correction, in which the temperature measured at the thermocouple is automatically adjusted using the measurement of the reference junction and the temperature-dependent resistance.

We will help you choose the right thermocouple

When selecting the thermocouples for your needs, you should also consider how high the acquisition costs are in the context of longevity and the planned service life. Depending on the materials used, there may be a deviation after too long a period of use without replacement. When we advise you on the purchase of a temperature sensor – be it a simple line thermocouple or a sheathed thermocouple type K – transparency and a fair representation of the price-performance ratio are always important to us. That is why we are happy to answer all of your questions regarding the longevity of various models and the differences between our many types of thermocouples. Regardless of whether you are looking for a jacket thermocouple, a screw-in model or an airflow thermocouple – thanks to our many years of experience and our holistic understanding of temperature measurement, we guarantee you the right solution for accurate results in your area of application.

Industrial thermocouples in various designs from Therma GmbH

Industrial thermocouples are an important industrial device used to measure temperatures in industrial environments. Using two dissimilar metals, industrial thermocouples convert thermal energy into an electrical signal and measure the temperature of equipment operating in extreme industrial conditions. The resulting changes are then detected by a monitoring device connected to the thermocouple, which generates an electrical signal. This detection process is instantaneous and is often installed in hard-to-reach or hazardous locations to ensure industrial safety and provide accurate readings of temperature changes in industrial systems. Industrial thermocouples are an efficient tool that helps maintain best industrial practices while reducing potential risks.