Sheathing thermocouples

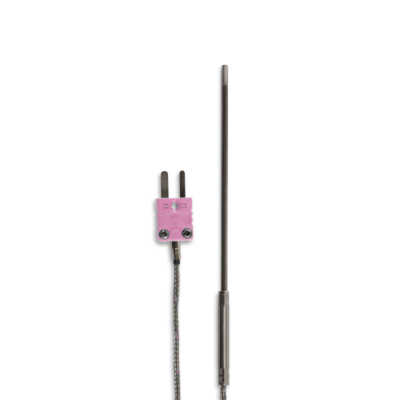

Sheathing thermocouples are robust and flexible and are freely bendable along their entire length. This means that the thermocouple can be integrated perfectly into its installation location. As a result, they can be used anywhere – whether in industry, development or in laboratory environments. The sheathing thermocouple can be effectively secured using a compression-type fitting and positioned directly on the measuring point. Sheathing thermocouples can also be used in extremely high temperatures, aggressive media, in vacuums or under pressure where conventional insulation materials would fail. The thermowire pair in this case is protected by a metal sheath and the wires are insulated against the sheath and each other using a mineral powder.

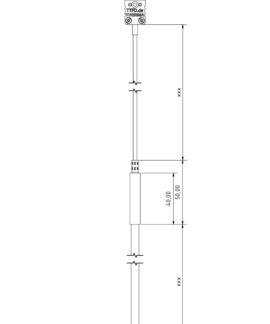

At one end of the thermowire (hot end), the wires are connected to a measuring point. The sheathing is then circular welded as standard and insulated against the measuring point so that no distortion of the measuring evaluation can occur as a result of offset overlay.

At the other end of the sheathing thermocouple, part of the sheathing is removed to expose the wires and establish a connection with the connecting wire that runs to the measuring device (cold end). The sheathing thermocouple is also sealed with a heat-resistant resin at this end. This sealing is required since the magnesium oxide (MgO) used for insulation is highly hygroscopic (water-attracting) and any penetrating moisture will lower the degree of insulation. Poor insulation distorts the measurement.

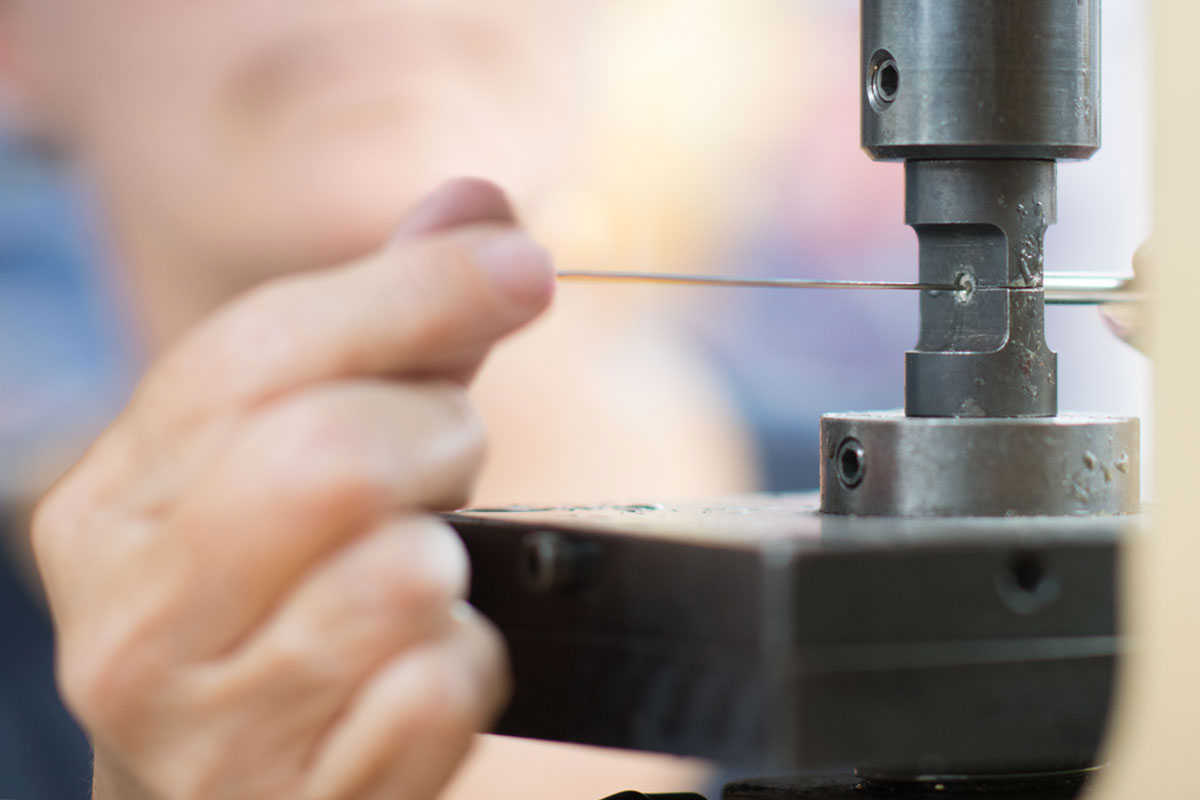

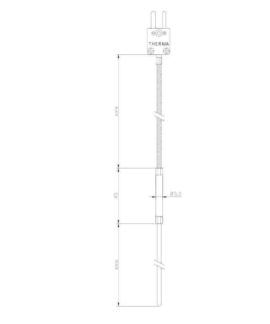

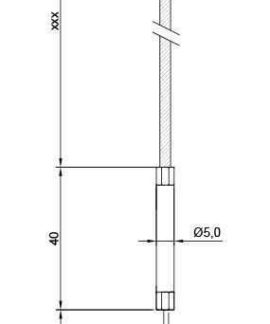

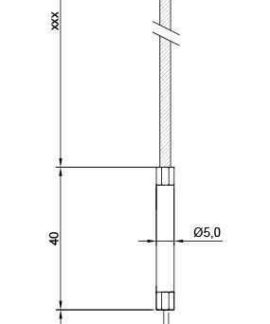

We are highly flexible in terms of the design of sheathing thermocouples and we can adapt them perfectly to our customers’ wishes. We offer sheathing thermocouples from a diameter of 0.25 mm and with any length. The sheathing is circular-welded as standard and insulated against the measuring point. On request, the sheathing can also be flat-welded or galvanically bonded to the measuring point.

It is also possible to choose different sheathing materials. Inconel600 is the sheathing material we use most often. In air, it has an oxidation resistance of up to +1,150 °C. It can also be used in a number of other media, including liquid sodium. Another sheathing material is stainless steel of type 1.4541. It can be used in a wide range of aggressive media. It is oxidation resistant up to 900 °C in air, and up to 650 °C in carbon dioxide. Nimonic75 is a nickel-chrome alloy. This alloy is especially suitable for use at high temperatures in aggressive media, since it is resistant to oxidation up to +1,100 °C even here. To measure even higher temperatures, platinum must be used as the sheathing material. This is generally only required in combination with thermocouple types R, S and B. In highly critical applications, the sheathing thermocouple can be installed in ceramic protective tubing.

It is also possible to choose different sheathing materials. Inconel600 is the sheathing material we use most often. In air, it has an oxidation resistance of up to +1,150 °C. It can also be used in a number of other media, including liquid sodium. A further sheathing material is 1.4541. It can be used in a wide range of aggressive media. It is oxidation resistant up to 900 °C in air, and up to 650 °C in carbon dioxide. Nimonic75 is a nickel-chrome alloy. This alloy is especially suitable for use at high temperatures in aggressive media, since it is resistant to oxidation up to +1,100 °C even here.

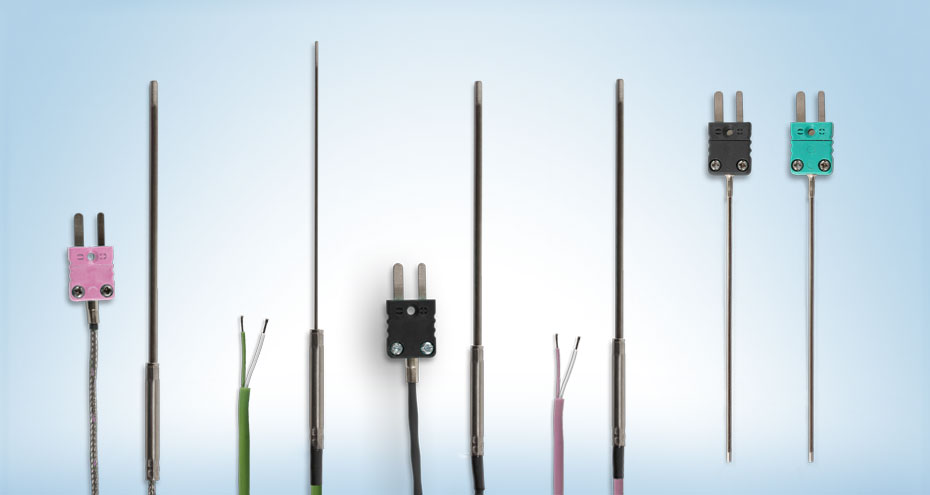

We also offer a wide range of connection configuration options. The sheathing thermocouple can be combined with various connecting wires. These can be supplemented with a broad array of connectors and sockets or equipped with exposed wire ends. It is even possible to install a connector or socket directly onto the sheathing thermocouple.

If you are unsure which sheathing thermocouple is best for your measuring application, or if you have very special expectations, then please get in touch with us. We would be more than happy to help you choose or develop the best measuring tool for your needs.

Typical area of application |

Pros |

Cons |

|---|---|---|

|

|

|

Images of sheathing thermocouples

Buy sheathed thermocouples online

Improve Your Process Control With Sheathed Thermocouples

In the realm of industrial process control, precision and reliability are paramount. Sheathed thermocouples offer a robust solution for temperature measurement, enabling businesses to enhance their operational efficiency and product quality. By incorporating these advanced sensors into your systems, you can achieve a level of control that was previously challenging to maintain.

Sheathed thermocouples consist of thermocouple wires encased in a protective metal sheath, providing durability and accuracy in harsh environments. This design allows for reliable temperature readings even in the presence of corrosive chemicals, high pressures, or extreme temperatures. We understand that maintaining consistent process parameters is crucial for your operations, and sheathed thermocouples offer the stability needed to achieve this goal.

One of the key benefits of using sheathed thermocouples is their versatility. These sensors can be customized to suit various applications, from food processing to petrochemical industries. The sheath material can be selected based on the specific requirements of your process, ensuring optimal performance and longevity. Whether you need to monitor temperatures in a furnace or a chemical reactor, sheathed thermocouples can be tailored to meet your unique needs.

Implementing sheathed thermocouples in your process control systems can lead to significant improvements in product consistency and energy efficiency. By accurately monitoring temperatures at critical points in your production line, you can make real-time adjustments to maintain optimal conditions. This level of control not only enhances product quality but also helps reduce waste and energy consumption, contributing to a more sustainable operation.

Understanding the Advantages of Thermocouple Sheathing

Thermocouple sheathing plays a crucial role in protecting the delicate sensing elements of thermocouples, offering numerous advantages that contribute to improved measurement accuracy and sensor longevity. By understanding these benefits, you can make informed decisions about implementing sheathed thermocouples in your processes.

One of the primary advantages of thermocouple sheathing is its ability to shield the thermocouple wires from harsh environmental conditions. The sheath acts as a barrier against corrosive substances, mechanical stresses, and electromagnetic interference, ensuring that the temperature readings remain accurate and reliable over time. This protection is particularly valuable in industrial settings where sensors are exposed to challenging conditions that could compromise their performance.

Another significant benefit of thermocouple sheathing is its contribution to faster response times. The sheath material is typically selected for its excellent thermal conductivity, allowing rapid heat transfer from the environment to the sensing element. This characteristic enables sheathed thermocouples to quickly detect temperature changes, providing you with near real-time data for precise process control.

Thermocouple sheathing also enhances the overall stability of the sensor. By minimizing the impact of external factors on the thermocouple wires, the sheath helps maintain the calibration of the sensor over extended periods. This stability translates to reduced maintenance requirements and fewer calibration cycles, ultimately leading to lower operational costs and improved process reliability.

How Sheathed Thermocouples Enhance Temperature Measurement Accuracy

Achieving high accuracy in temperature measurement is critical for many industrial processes, and sheathed thermocouples excel in this regard. The design and construction of these sensors contribute significantly to their ability to provide precise and reliable temperature readings across a wide range of applications.

One of the key factors that enhance the accuracy of sheathed thermocouples is their improved resistance to electromagnetic interference (EMI). The metal sheath acts as a Faraday cage, shielding the thermocouple wires from external electrical noise that could otherwise distort the temperature signal. This protection is particularly valuable in environments with high levels of electromagnetic activity, such as near large motors or power systems.

Sheathed thermocouples also benefit from reduced thermal shunting effects. The sheath helps to isolate the sensing junction from the surrounding environment, minimizing unwanted heat transfer along the thermocouple wires. This isolation ensures that the temperature measured at the tip of the sensor more accurately reflects the true temperature of the medium being monitored, rather than being influenced by conditions further along the sensor’s length.

Furthermore, the compact design of sheathed thermocouples allows for more precise positioning within the process. You can insert these sensors into specific locations where temperature measurement is most critical, ensuring that you obtain accurate data from exactly where you need it. This capability is especially valuable in applications with steep temperature gradients or in processes where localized temperature control is essential.

Selecting the Right Sheathed Thermocouple for Your Application

Choosing the appropriate sheathed thermocouple for your specific application is crucial to ensure optimal performance and reliability. We understand that each industrial process has unique requirements, and selecting the right sensor involves considering several key factors.

First and foremost, you need to consider the temperature range of your application. Different thermocouple types (such as Type K, J, or N) are suitable for different temperature ranges. For instance, Type K thermocouples are widely used due to their broad temperature range, while Type R or S thermocouples are better suited for extremely high-temperature applications. We can help you determine which type best matches your process conditions.

The choice of sheath material is another critical factor. Common materials include stainless steel, Inconel, and ceramic, each offering different properties in terms of corrosion resistance, temperature capability, and mechanical strength. For example, if your process involves corrosive chemicals, a sheath made from Inconel might be the best choice due to its excellent resistance to chemical attack.

The diameter and length of the sheathed thermocouple also play important roles in its performance. Smaller diameters generally offer faster response times but may be less durable in harsh environments. Longer probes can reach deeper into processes but may require additional support to prevent bending or breakage. We can work with you to determine the optimal dimensions based on your specific installation requirements and process characteristics.

Consider also the termination style of the thermocouple. Options include bare wire endings, terminal heads, or connectors. The choice depends on your instrumentation setup and environmental conditions. For instance, in areas with high humidity, a sealed terminal head might be preferable to protect the electrical connections.

Lastly, think about any special requirements your application might have. Do you need a grounded or ungrounded junction? Is vibration a concern in your process? Are there any certifications or standards that the thermocouple must meet? By addressing these questions, we can help you select a sheathed thermocouple that not only meets your current needs but also provides long-term reliability and accuracy in your temperature measurement tasks.