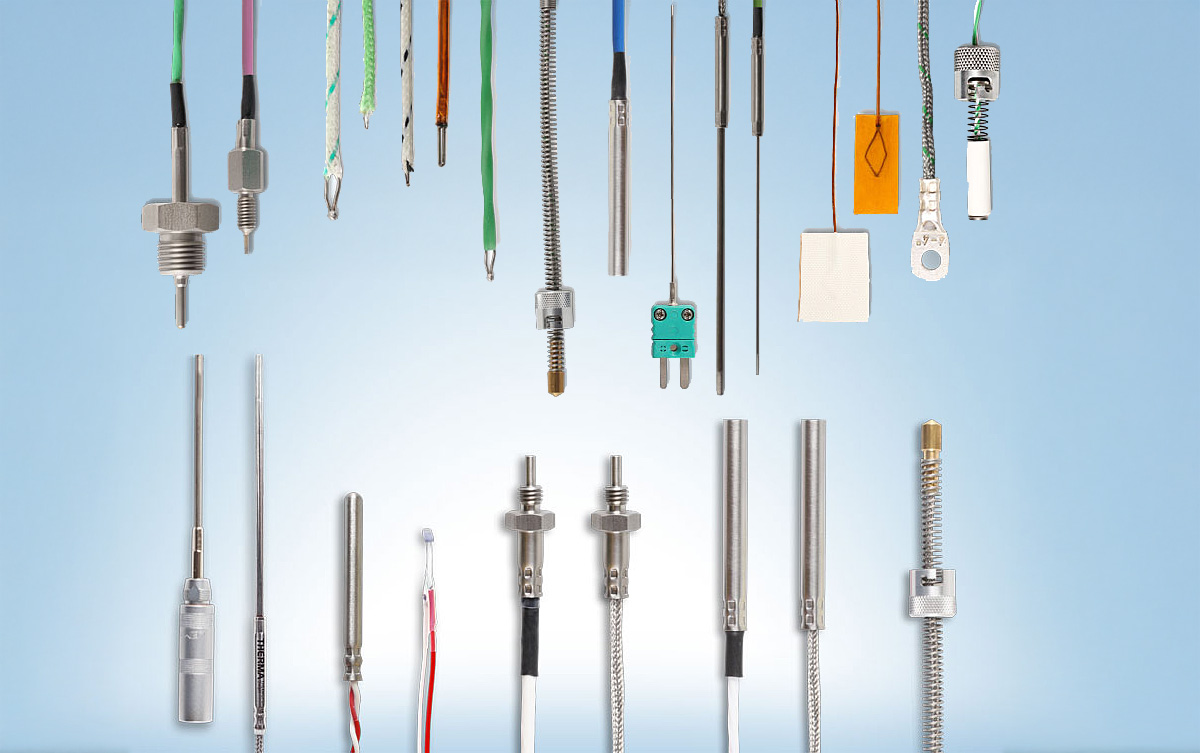

- Thermocouples

- Screw-in thermocouple

- Plug-in thermocouple

- Dipstick-Thermocouples

- Wire thermocouple

- Sheathing-tube thermocouples

- Sheathed thermocouple

- Surface thermocouple

- Screw-in resistance thermometer

- Plug-in resistance thermometer

- Wire resistance thermometer

- Sheating tube resistance thermometer

- Sheathing resistance thermometer

- Accessories Thermocouples

- Surface resistance thermometer

- Sheathed thermocouple with terminal head

- Thermo connectors

- More products

Thermocouples vs. resistance thermometer: The comprehensive comparison for optimal temperature measurement

When selecting temperature sensors, engineers and technicians are often faced with an important decision: thermocouples or resistance temperature detectors? Both sensor technologies have their specific strengths and areas of application. While resistance temperature detectors impress with their exceptional measuring accuracy, thermocouples score points for their robustness and suitability for high temperatures. This comprehensive comparison will help you find the optimal sensor solution for your application.

What are thermocouples and resistance thermometers?

Basics of thermocouples

Thermocouples are based on the physical principle of the thermoelectric effect. This involves electrical voltages being generated by temperature differences between two different metal alloys. These sensors consist of two interconnected wires made of different materials, with the connection point serving as the measuring point.

The variety of available thermocouple types enables applications in a wide range of areas:

-

- Type K: Nickel-chromium alloys for medium temperature ranges

- Type S: Platinum-rhodium combinations for extreme heat

- Type J: Iron-constantan for cost-effective standard applications

The robust design of these sensors is particularly noteworthy. Mechanical stress, vibrations, and aggressive environments have little effect on their functionality. This resistance makes thermocouples the first choice in industrial processes with harsh conditions.

Resistance thermometers at a glance

Resistance thermometers utilize the temperature-dependent change in electrical resistance of metals. Platinum is the preferred material due to its excellent linearity and chemical resistance. The resistance value increases proportionally to the temperature increase, enabling precise measurements.

Pt100 sensors are the industry standard and have a base resistance of 100 ohms at 0°C. This standardization ensures consistent measurement results and simplifies exchange between different devices. The high reproducibility of the measured values makes these sensors particularly valuable for calibration tasks.

Platinum as a sensor material offers decisive advantages due to its chemical inertness. Oxidation processes or other environmental influences have only a minimal effect on measurement accuracy. This stability results in long calibration intervals and reduced maintenance costs over the entire service life of the sensor.

Thermocouples vs. resistance thermometers: the most important differences

Measurement accuracy and precision

| Property | Resistance thermometer | Thermocouples |

|---|---|---|

| Tolerance at 0°C | ±0.1°C to ±0.3°C | ±0.5°C to ±2.5°C |

| Long-term stability | Excellent | Satisfactory |

| Calibration intervals | 2-5 years | 6-12 months |

Resistance thermometers significantly outperform thermocouples in terms of measurement accuracy. This accuracy results from the linear resistance characteristics of platinum and the stable measurement principles. Additional uncertainties arise with thermocouples due to the necessary compensation of the reference junction.

Long-term stability is another difference. Pt100 sensors retain their calibration for years, while thermocouples require more frequent checks due to material drift and chemical changes. This property has a significant impact on both maintenance costs and total operating costs.

Temperature range and application limits

Thermocouples clearly dominate in high-temperature applications. Special types can measure ranges up to 1800°C, while standard Pt100 sensors reach their limits at around 600°C. This characteristic makes thermocouples indispensable for melting processes, furnaces, or turbine applications.

Low-temperature measurements show the opposite conditions. Resistance thermometers function reliably down to -200°C, while many thermocouple types deliver unusable signals in extreme cold. Cryogenic applications therefore usually require resistance-based solutions such as Pt100 or Pt1000.

The choice of temperature range has a significant influence on the sensor decision. Processes with moderate temperatures benefit from the precision of resistance thermometers, while extreme heat requires the use of robust thermocouples.

Advantages of resistance thermometers over thermocouples

Superior measurement accuracy

Precision measurements require the exceptional accuracy of resistance sensors. Laboratory applications, quality control, and calibration tasks benefit from minimal measurement tolerances. This precision enables the detection of even the smallest temperature fluctuations, which can be critical in critical processes.

The most important accuracy advantages at a glance:

- Reproducibility: Identical measured values with different sensors

- Linearity: Uniform characteristic curve over the entire measuring range

- Stability: Minimal drift over many years

Chemical insensitivity of platinum prevents measurement drift due to environmental influences. Aggressive media or corrosive atmospheres have little effect on sensor characteristics, provided that suitable protective tubes are used. This resistance leads to extended maintenance intervals and reduced operating costs.

Strengths of thermocouples in direct comparison

Fast response times and robustness

Dynamic temperature measurements require extremely short response times. Thermocouples respond to temperature changes within milliseconds, while resistance thermometers respond much more slowly due to their greater thermal mass. This speed makes them indispensable for control tasks and process monitoring.

Thermocouples are particularly characterized by their mechanical robustness:

- Vibration resistance up to high frequencies

- Impact resistance under mechanical loads

- Insensitivity to pressure fluctuations

Compact designs enable measurements in hard-to-reach places. The point-shaped measuring point accurately records local temperatures, while larger resistance thermometers provide average values across their entire sensor surface.

Cost efficiency and ease of maintenance

Economic considerations often favor thermocouples. Acquisition costs are usually lower than for comparable resistance thermometers, especially for standard designs. These cost advantages multiply significantly in systems with many measuring points.

Simple installation reduces commissioning costs. Thermocouples do not require an external power supply.

Ease of maintenance is evident in their robust construction and low susceptibility to mechanical damage. Even after years of intensive use, most thermocouples remain functional, but require more frequent calibration than resistance thermometers.

Decision-making aid: When is which sensor the right choice?

Application criteria for resistance thermometers

Precision measurements are the main area of application for resistance sensors. Pharmaceutical processes, food production, and laboratory applications benefit from their exceptional accuracy. Quality assurance and documentation requirements often demand the precise measurements provided by this sensor technology.

Optimal areas of application for resistance thermometers:

- Long-term monitoring in stable environments

- Calibration tasks and reference measurements

- Process control with high accuracy requirements

- Documentation-required applications

Calibration intervals for high-quality resistance sensors can be several years. This long-term stability makes them the preferred choice for critical applications where measurement deviations could have costly consequences.

Areas of application for thermocouples

High-temperature applications require the heat resistance of thermocouples. Exhaust gas measurements, steel production, glass manufacturing, and ceramic processes far exceed the temperature limits of resistance thermometers. Special types of thermocouples can easily withstand even the most extreme temperatures.

| Scope of application | Temperature range | Preferred sensor type |

|---|---|---|

| Steel production | 1000-1600°C | Typ S, Typ R |

| Internal combustion engines | 200-1200°C | Typ K, Typ N |

| Cryogenic processes | -200 to 0°C | Pt1000 |

Dynamic measurement processes benefit from short response times. Combustion engines, rapid heating processes, and temperature control systems require the millisecond response times offered by these sensors. Control technology can only achieve optimal results with sufficiently fast temperature signals.

Harsh environments with mechanical stresses, vibrations, or chemical attacks require robust sensor solutions. Heavy industry, mining, and aggressive process media pose challenges that only resistant thermocouples can meet.

Conclusion: The optimal sensor choice for your temperature measurement

The decision between thermocouples and resistance thermometers depends primarily on the specific application requirements. Precision and long-term stability favor resistance sensors, while robustness and high-temperature suitability favor thermocouples.

Decision criteria at a glance:

- Required measurement accuracy and tolerances

- Operating temperature range and environmental conditions

- Response time and dynamic requirements

- Maintenance costs and lifetime costs

Different industries show clear preferences: The pharmaceutical and food industries rely on precise resistance thermometers, while metal processing and energy production prefer robust thermocouples. The optimal solution takes all relevant factors into account and ensures reliable temperature measurements over the entire service life of the plant.